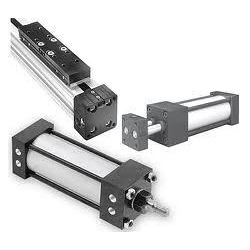

HomePneumatic Cylinder

Pneumatic Cylinder

Materials of Construction

Materials of Construction

- End caps – Aluminium diecast / Cast Ion

- Tie rod – Tensile Steel Zinc Plated

- Piston – Aluminium machines

- Cylinder Tube – Upto dia 4″(100mm) in brass, dia 5″(125 mm) & above upto dia 12 M.S. seam less honed & hard Chrome plated.

- Piston Rod – High Tensile Steel Hard Crome Plated

- Seals – High Nitrile 3307

Features

- Heavy duty & Robust constructions.

- Single & double acting models are available in Ten bore sizes from 25mm to 200mm.

- Adjustable cushioning for reducing impact of stroke at both cylinder ends is standard for all models. (Bore more than 1″)

- Selection of attachments for six mounting styles.

- Super finished and hard-chrome plated high tensile steel piston rods.

- Pressure Temperature

- Operating pressure upto 10kg f/cm2 for air upto 25kg f/cm2 for oil

- Operating Temperature Max. 80o c.

Mountings – Suffix

- Rear Flange – RF : Front Trunion – FT

- Rear Trunion – RT : Centre Trunion – CT

- Clevis Mounting – CM : Front Flange – FF

- Foot Mounting – FT : Neck Mounting -NM

- For piston Rod Fork Attachment Suffix – RK.

Pneumatic cylinders are available in different sizes, types and are traded strictly in compliance with ISO standards. Apart from these air / pneumatic cylinders is available in different types of cylinders like single acting & double acting pneumatic cylinders, hydraulic cylinders (weldable type, tie rod type), hydro pneumatic cylinders, standard cylinder, slim cylinder, compact cylinder etc.

Pneumatic cylinders are available in different sizes, types and are traded strictly in compliance with ISO standards. Apart from these air / pneumatic cylinders is available in different types of cylinders like single acting & double acting pneumatic cylinders, hydraulic cylinders (weldable type, tie rod type), hydro pneumatic cylinders, standard cylinder, slim cylinder, compact cylinder etc.

Our Products

[accordionmenu id="unique77cdf28" accordionmenu="4190"]